In the recent installments of our VPP blueprint series, we explored how Virtual Power Plants can make clean energy more accessible and our grids more flexible. We illustrated that interfaces and regulations are key when aggregating distributed energy resources into cohesive virtual connected assets, and that forecasting data plays a vital role in planning a VPP’s production schedule. VPPs, however, will only be able to overcome integration challenges if their potential is harnessed to a high degree. Only then will we be able to scale renewables and flexible distributed technologies.

This is why in this Part 4 of our VPP blueprint series, we will focus on optimization, the heart of a VPP’s operation, which makes or breaks the profits your VPPs earn. Optimizing the ideal size of assets connected depends on balancing the connection costs and optimization abilities, as higher connection costs determine a minimum viable asset size to cover those costs. Here, a higher degree of optimization can extract more value from smaller assets by improving returns, allowing for smaller asset sizes to be profitably connected given the same connection costs. This advantage, however, comes with the difficulties of solving large-scale multi-period operational problems, all while dealing with uncertain variables and balancing solution quality and computational speed.

In the first article of this series, we already described how forecasting plays a vital role in determining how a Virtual Power Plant participates in electricity markets. It involves using statistical techniques and historical data to predict future conditions that serve as inputs to optimization models. Optimization then takes it from here and calculates the technically feasible and economically optimal schedules and dispatch decisions for the VPP's distributed energy resources, by formulating and solving mathematical problems based on the forecasts and operational limitations.

The optimization engine

At the core of any VPP is an optimization engine, the sophisticated software responsible for calculating schedules and establishing real-time operational dispatch targets for all participating DERs. It must calculate exactly how and when each DER will consume or deliver power to fulfill all contractual obligations as a result of previous market participation. Solving this dispatch scheduling task over multiple periods, while accounting for technical constraints, uncertainty factors, and profit optimization goals, is an immensely complicated undertaking. But do not despair, as the brightest minds are already working on it.

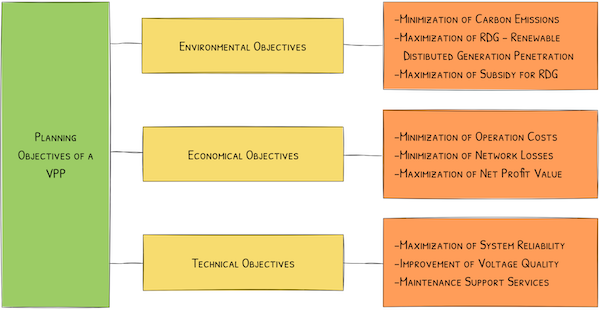

There are two areas in which a VPP must be optimized:

Structural optimization of the VPP

Structural optimization of the VPP involves determining the optimal configuration of the distributed generation resources, energy storage units, and loads/consumption units that make up the VPP. This type of optimization is only possible for a new or planned VPP system, as it requires selecting each component's capacity and suitable location. The goal is to choose a structure that maximizes benefits like minimizing costs, losses, and emissions while improving voltage profiles, reliability, and power quality.

Analytical, numerical, and heuristic optimization methods can be used to determine the best sizing and placement of distributed generation units within the VPP system. Common approaches include linear programming, nonlinear programming, dynamic programming, genetic algorithms, and firefly algorithms. A high-functioning VPP optimization solution considers myriad inputs to inform these complex calculations. At a minimum, optimization modeling requires access to load and renewable production forecasts, contracted services terms, dispatch instructions from system operators, historical and real-time market pricing data, as well as up-to-date operating parameters for all participating DERs.

Operational optimization of the VPP

Once a VPP system is established with predefined sizing and siting of its components, ongoing operational optimization is required to effectively manage the system on a daily and real-time basis. This includes calculating production schedules, charge/discharge rates, and market participation to minimize costs while balancing supply and demand across the portfolio.

A key aim of operational optimization is to maximize revenue by providing grid services such as ancillary reserves and participating in electricity markets like intraday and day-ahead. It continuously answers critical questions about real-time system dispatch:

- When energy prices rise or demand increases, should the VPP generate more power, reduce loads, or draw from energy storage? The optimization calculates the lowest cost solution and specific assets to adjust.

- Which distributed generators should ramp up production - the solar panels, wind turbines, or backup diesel generators?

- Should battery storage systems begin discharging or should controllable loads like EV chargers reduce consumption?

- Conversely, when prices drop or demand decreases, should the VPP reduce generation, allow more loads, or use excess energy to recharge batteries?

- Which generators should ramp down or shut off - the solar, wind, diesel, or all three?

- Should battery storage charge up or controllable loads increase consumption of low-cost renewable energy?

By addressing these questions across short time intervals, the optimization dynamically manages the VPP portfolio to minimize costs, balance supply and demand in real-time, and take advantage of hourly price variations in electricity markets.

Optimization calculations are performed across 1-6 hour look-ahead periods aligned with market products. Monitoring and control systems track each distributed energy resource's real-time operating state and performance. Adjustments are made to dispatch reserves if an asset goes offline or isn't performing as expected, ensuring reliability.

A diverse portfolio of VPP assets, with, e.g., batteries, diesel generators, hydro pump-turbine storages, could offer all services as Ancillary Services (FCR, aFRR, mFRR), as well as on intraday and day-ahead markets. Asset characteristics like minimum up/down times, ramp rates, and health status are modeled to match the technical capabilities of different resources to the proper grid services. Here, batteries provide fast reserves, while generators are better for day-ahead markets. This, however, requires sophisticated technical optimization of a diverse multi-asset portfolio that optimizes flexibility to stack revenues across services, a topic that we will cover in the subsequent article on Trading Strategies.

Dealing with uncertainty

However, hitting this critical problem perfectly is nearly impossible given real-world complexities. For example, operational demands for solutions with fast run times necessitate pragmatic trade-offs versus exhaustive modeling techniques. Limitations are inevitable to deliver timely results, impacting optimization quality. Similarly, quality inputs are crucial but forecasts are imperfect and unexpected events occur. Even the most sophisticated algorithms will struggle without clean, accurate data to rely upon. The scale also challenges deterministic solutions; deterministic modeling simply cannot incorporate full uncertainty realities

Reliability of delivery poses an ongoing difficulty as well. DERs do not always generate or consume precisely as optimization expects due to variable weather or component risk. Without countermeasures, this could jeopardize service commitments. Careful planning factors in ways to avoid reliability issues through redundancy or real-time adjustments.

The sheer scale of coordinating optimization for large distributed assets indicates an important role for specialized software development. Commercial and utility-scale VPPs integrate assets numbering in the tens or even hundreds of MW, requiring commensurately powerful solutions. Advanced optimization approaches that offload processing onto parallel computing architectures are necessary to manage VPPs of meaningful size.

The “art of the possible”

These types of technical considerations are elevating the “art of the possible” for multi-market, reliability-focused VPP operations. Here, machine learning techniques help refine forecasts while tight feedback controls address variances. Emerging "agent-based" control paradigms may even distribute optimization tasks among ‘agents’ representing individual DERs for enhanced scalability.

Maximizing distributed generation

Continued evolution of VPP technologies will be crucial to realizing cleaner, lower-cost electricity futures defined by ubiquitous DER integration. Optimization capabilities determine how completely the diverse value propositions comprising VPP services can be commercialized. For a sustainable industry, pursuit of advanced multi-period optimization for dispersed portfolios of resources will be the way to maximize distributed generation’s potential for 21st-century grids.

Next up we will talk about trading strategies that define the high-level approach for how the VPP will participate across multiple markets over time, considering factors like current and expected market conditions, asset capabilities and limitations. When optimization determines real-time schedules, trading strategies guide how optimization formulations are structured to maximize value extraction through different market participation approaches.

The Navitasoft VPP Blueprint

Follow our complete series on VPPs and the digital solutions needed to run them:

Part 1: Forecasting in virtual power plants

Part 2: Integrating virtual power plants

Part 3: Internal system integration and reporting

Part 4: Optimization in Virtual Power Plants

Part 5: Trading Strategies to Optimize Your VPP

Part 6: How to Manage Risk for Your Virtual Power Plant

Part 7: Dispatching & control of execution in virtual power plants

Part 8: Disaggregation and settlement in virtual power plants

Part 9: VPP 3.0 - The Third Generation of Virtual Power Plants